The rare earth elements (REE) are a continuous series of fifteen elements from lanthanum to europium, comprising the light fraction (LREE), and gadolinium to lutetium accompanied by yttrium and scandium that comprise the heavy fraction (HREE). Despite their group name these elements are more common than many better known elements and they are metallic in character.

The REE are relatively abundant in the earth’s crust, but minable concentrations are less common than for many other ores. REE have been steadily growing in importance because of their value in many cutting-edge technologies such as automotive catalytic converters, wind power generators, phosphors for flat screens, LED and CFL lighting, high strength magnets, chemicals and petroleum refining catalysts, pharmaceuticals and metallurgical additives and alloys. For this reason there is today substantial exploration and evaluation of REE deposits around the world.

Besides the total REE concentration, the value of a certain deposit is determined by the balance between the LREE, which usually comprise 97-99% of the resource, and the HREE such as dysprosium and terbium which are of much higher value.

What distinguishes rare earth mineral deposits from commodities like copper or lead is the fact that the rare earths occur in a large variety of different minerals and geological settings and generally in very low concentrations. Even if their general crustal abundance is not low (a few tens ppm), the often very complex nature of mineralization (more than 200 rare earth bearing minerals known) makes the feasibility of extracting the REE from the ore an extremely challenging task. Since the know-how in this specialized field is scarce and concentrated in very few places the term “rare” in REE refers rather to the restricted availability of these metals in a usable form than to the number of deposits.

What distinguishes rare earth mineral deposits from commodities like copper or lead is the fact that the rare earths occur in a large variety of different minerals and geological settings and generally in very low concentrations. Even if their general crustal abundance is not low (a few tens ppm), the often very complex nature of mineralization (more than 200 rare earth bearing minerals known) makes the feasibility of extracting the REE from the ore an extremely challenging task. Since the know-how in this specialized field is scarce and concentrated in very few places the term “rare” in REE refers rather to the restricted availability of these metals in a usable form than to the number of deposits.

In general REE bearing minerals are found in the following primary and secondary geological settings:

- Carbonatites (almost exclusively LREE)

- Pegmatites

- Hydrothermal veins (enriched in HREE)

- Weathered deposits/Laterites (Ion adsorption clay)

- Placers (mostly sands of marine origin)

The deposit with the world’s largest known REE resources is situated in Bayan Obo, Inner Mongolia, where three different types of ore are distinguished: Iron-REE ore, REE ore in dolomite and REE ore in silicate rock. Economically exploited minerals are bastnaesite and monazite. The genetic origin of the deposit is still a matter of debate.

The deposit with the world’s largest known REE resources is situated in Bayan Obo, Inner Mongolia, where three different types of ore are distinguished: Iron-REE ore, REE ore in dolomite and REE ore in silicate rock. Economically exploited minerals are bastnaesite and monazite. The genetic origin of the deposit is still a matter of debate.

Other considerable occurrences of rare earth mineral resources are related to alkaline igneous intrusive complexes and carbonatites such as Mountain Pass and Mount Weld. Main ore minerals in these deposits are bastnaesite, allanite, monazite and apatite and pyrochlore in the latter.

Of economical importance are also the REE laterites which are formed by weathering of REE-rich alkaline complexes. Apatite, pyrochlore and monazite are typical residual and crandallite group minerals typical secondary minerals formed during weathering. The deposits of Xunwu and Longnan in the Jiangxi Province in China, which form the weathered crust of a granitic rock are exploited for their ion adsorption clays which are rich in HREE.

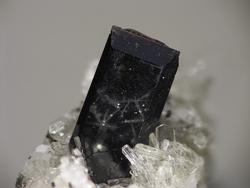

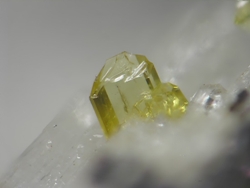

There is a wealth of different REE bearing minerals. REE are found in almost all mineral groups including silicates (e.g. eudialyte, allanite, zircon, steenstrupine etc.), fluoro-carbonates (e.g. bastnaesite, synchisite, parisite, fluocerite), oxides (e.g. euxenite, fergusonite, pyrochlore, loparite, cheralite) and phosphates (e.g. xenotime, churchite, florencite, britholite, apatite).

There is a wealth of different REE bearing minerals. REE are found in almost all mineral groups including silicates (e.g. eudialyte, allanite, zircon, steenstrupine etc.), fluoro-carbonates (e.g. bastnaesite, synchisite, parisite, fluocerite), oxides (e.g. euxenite, fergusonite, pyrochlore, loparite, cheralite) and phosphates (e.g. xenotime, churchite, florencite, britholite, apatite).

Today, generally three mineral species, i.e. bastnaesite, a LREE fluorocarbonate (China and USA); monazite, a LREE/HREE phosphate (Australia) and xenotime, a HREE yttrium phosphate (Malyasia) as well as lateritic ore containing HREE rich ion adsorption clays in China are exploited commercially. Besides, loparite is processed in Russia to extract REE enriched in the Lovozero Complex.

Due to similar physical and chemical properties the different rare earth elements (REE) occur together and are recovered from their mineral host as a mixture of different REE. Subsequent sequential chemical processing to separate and concentrate individual REE to high levels of purity involves additional cost. In most deposits, the balance is tipped towards the light rare earth elements (LREE) which comprise 97-99% of resources. In contrast, deposits having an unusual balance with a high proportion of heavy rare earth elements (HREE) are very rare. Many of the HREE play a crucial role in emerging green energy and high tech applications together with the fast growing demand in the lighting industries (LED), however, rendering HREE much more valuable than LREE.

Bastnaesite deposits in China and the USA constitute the largest percentage of the world’s rare earth reserves, while monazite deposits in Australia, Brazil, China, India, Malaysia, South Africa, Sri Lanka, Thailand, and the United States constitute the second largest segment.

There are two major REE ore minerals from which predominantly LREE can be extracted with relative ease: bastnaesite and monazite.

There are two major REE ore minerals from which predominantly LREE can be extracted with relative ease: bastnaesite and monazite.

Bastnaesite, a fluorocarbonate mineral and monazite, a phosphate, contain predominantly either cerium, lanthanum or yttrium.

The world-class rare earth deposit Mountain Pass (California, USA), operated by Molycorp, contains bastnaesite ore as part of a carbonatite body (8-12 % REO) intruded into gneiss.

At the Mountain Pass operation the run of mine material is passed through a cascade of physical processing steps including crushing, screening, grinding and flotation finally producing a bastnaesite pre-concentrate from which products with different REO contents are derived in subsequent thermal and chemical processing steps.

The REE mineral concentrate is digested in hydrochloric acid and the resulting REE laden liquor is passed through a sequence of solvent extraction with several mixer-settler steps. Final products of this element-selective extraction processes are either separated REO or other products following customer requirements.

The Mount Weld (southern Western Australia) REE deposit representing the laterized cap of a large carbonatite shows generally high LREE/HREE ratios with locally enriched HREE and yttrium which are present in secondary phosphates such as crandallite and xenotime.

Physical concentration of the REE minerals is performed at Mount Weld. The run of mine material is subjected to crushing, grinding and flotation to produce a concentrate with a grade of 40% REO. The obtained flotation concentrate is sent to a thickener, the resulting pulp is dewatered by applying a pressure filtration.

The separation into individual REO is carried out at Lynas Advanced Materials Plant in Malaysia. Here the mixed REO concentrate is cracked with sulfuric acid and leached with water. The pH is then reduced by addition of magnesium oxide and precipitated by-products are filtered off. At the separation stage the solution is mixed with hydrochloric acid and extracted in individual extraction stages using organic chemicals to separate the RE chlorides and remove impurities. In the final stage the different extraction liquids are treated with sodium carbonate, neutralized with magnesium oxide and precipitated with sodium carbonate solution or oxalic acid. Precipitated products are filtered and either further treated to obtain RE oxide or carbonate products.

Other major monazite sources are heavy mineral sands from so-called placerdeposits which are usually mined by dredging or scraping, followed by screening and concentration in spiral concentrators. Mineral concentrates are then washed, dried and fed into magnetic separators to remove e.g. ilmenite and other magnetic minerals. In a subsequent step electrically conducting and nonconducting heavy minerals are typically separated in electrostatic plate separators followed by induced roll separators that help to distinguish induced magnetic from non-magnetic minerals (i.e. xenotime and monazite from zircon). The former two minerals can then be separated by wet table or air table taking advantage of their slightly different specific gravities.

The monazite concentrate is typically digested in hot sulfuric acid and partially neutralized. Upon addition of Na2SO4 the lighter REE can be precipitated from the sulfuric solution which holds the remaining heavier REE.

An example of such a placer rutile-zircon-ilmenite deposits is at Eneabba on Australia’s west coast north of Perth, which produced about 2,500 t of monazite annually, with monazite making up 0.5% to 7.0% of the heavy minerals. Present-day production is from India, Malaysia, Sri Lanka, Thailand, and Brazil. In India, monazite production from titania-zircon placers is government controlled, and a domestic plant processes monazite concentrate into REE products.

The highly valuable HREE are currently largely sourced either from xenotime or from ion adsorption clays with the largest deposits and operations located in China, e.g. in the Guangdong, Hunan, Jiangsu and Jiangxi provinces.

Processing of these clays is a fairly simple, low cost operation involving typically ion exchange by washing with (NH4)2SO4, removal of U and Th from the pregnant solution, precipitation of RE carbonates, filtering and calcination to obtain a mixed REO concentrate which can the further be separated and purified into individual REO. Recovery of REE in these operations typically exceeds 90%.

An interesting alternative source of HREE is eudialyte, a common zirconosilicate and principal ore mineral in a number of alkaline igneous REE ore deposits rich in HREE. It can be readily dissolved in different acids, making contained REE amenable to further hydrometallurgical processing.

A principal HREE deposit with above mentioned zirconosilicates is the Norra Kärr deposit in Sweden, which is a peralkaline intrusion hosted rare earth element and zirconium mineralization with predominantly HREE bearing ore minerals such as eudialyte and catapleiite. Processing of the ore involves crushing, grinding and magnetic separation to obtain a REE bearing zirconosilicate (eudialyte) mineral concentrate and feldspar/nepheline and aegirine byproducts. The REE mineral concentrate is then sent to a sulphuric acid digestion followed by subsequent solid/liquid separation and further purification steps to finally obtain an REE carbonate and a zirconium bicarbonate product.

GPE is not restricted to the above mentioned REE ore minerals but has a proven history in the development of processing concepts adapted to specific REE mineral assemblages including the concentration and hydrometallurgical REE extraction from less well known REE bearing pay minerals such as apatite, eudialyte, allanite, zircon, euxenite, fergusonite, pyrochlore, florencite and churchite taking full advantage of its close link between analytical and engineering department.

After concentration REE bearing minerals, rare earth elements have to be extracted from the concentrate.

After concentration REE bearing minerals, rare earth elements have to be extracted from the concentrate.

Several procedures for decomposition of REE bearing minerals are available. The major part includes thermal treatment of the ore in the presence of acidic or caustic reagents. Depending on the composition of the ore concentrate an appropriate method is identified.

Acid baking with sulfuric acid is a very common process. The powdered ore is mixed with concentrated sulfuric acid and baked at temperatures between 200 and 400 °C for several hours. The resulting cake is leached with water to dissolve REE as sulfates. Optimal reaction conditions and reagent use have to be matched specifically with each tested ore. There are different factors influencing the reaction, e.g. the presence of iron oxide leading to an increased consumption of acid. At roasting temperatures above 300 °C the recovery of REE decreases in most cases, while Th leaching is also reduced. Since thorium is generally an undesired leaching product, roasting temperature will be a trade-off between REE recovery and Th leaching.

Acid baking is a standard process since it is applicable for many of the common rare earth minerals such as monazite, bastnaesite, xenotime, apatite or aeschynite.

Decomposition in HCl is commonly applied for carbonate minerals like bastnaesite, parisite, synchisite or similar minerals but can be also used to decompose allanite, cerite or gadolinite. The ore is stirred in concentrated HCl at temperatures > 90 °C. If the ore contains fluorine (e.g. bastnaesite), a part of the REE forms insoluble REE-fluorides remaining in the solid residue. To recover those REE the solid residue has to undergo an additional decomposition with sodium hydroxide, to convert the fluorides into hydroxides and soluble sodium fluoride. Fluorides are washed away and REE hydroxides are dissolved by excess HCl in the leaching liquor from the HCl decomposition step.

In the presence of calcite or similar carbonate phases in the ore, a leach with diluted HCl at room temperature is appropriate to purify the ore prior to decomposition as these reaction conditions will dissolve unwanted carbonate phases without attacking bastnaesite.

A special ore is eudialyte. It is easily soluble in any mineral acid thus decomposition is rather simple. Nevertheless, it is often accompanied by zeolites, which tend to form silica gels upon dissolution in acid. Depending on the zeolite content different precautions have to be taken during decomposition to minimize the formation of gels.

Alternatively caustic decomposition can be applied to specific ores. The most common process is decomposition with sodium hydroxide being applicable for monazite and bastnaesite. The ore is mixed with 50-60 wt.-% NaOH and is decomposed at T > 140 °C. Rare earths are transformed to hydroxides, while phosphates (from monazite) or carbonates and fluorides (from bastnaesite) are transformed into soluble sodium salts that can be washed off. The resulting solids are leached in diluted HCl.

The choice of decomposition method depends on various factors. Often caustic decomposition results in more pure products, but if the ore contains several different minerals a process capable of decomposing all of them has to be defined. Since in most cases non-neglibile amounts of non REE-containing side components are present in the mineral concentrates, the effectivity of a process will usually be affected by the latter. Another point to be taken into consideration is regional availability of reagents.

Once REE are solubilized, they have to be separated from co-leached elements. After removal of impurities e.g. by pH dependent precipitation, REE are typically precipitated as oxalates or carbonates, from which REE-oxides can be obtained by calcination. If necessary, residual thorium can be removed from the oxides by dissolving them in nitric acid and extraction of the resulting solution with organophosphates.

GPE uses its in-house technical center and selected machine manufacturer’s equipment for tailor-made process development and to provide samples for end user approval. This can be a mineral concentrate or the precipitated mixed REE compounds.

GPE’s bench scale and pilot plant processing facilities cover the value chain of REE ore processing from the liberation and concentration of REE bearing minerals to extraction of REE’s and purification of mixed REE compounds as final products.

Besides the more conventional REE bearing minerals like bastnaesite or monazite we especially develop specific processing and extraction routes tailored for the less well known REE bearing pay minerals such as apatite, eudialyte, allanite, zircon, euxenite, fergusonite, pyrochlore, florencite and churchite taking full advantage of its close link between analytical and engineering department.

Concentration of REE bearing minerals

In our pilot plant REE ore mineral concentrates are produced and provided for customer approval. Since REE bearing minerals are usually present in minor quantities special attention is paid to potential by-products which may create additional revenue.

The GPE technical center is well equipped and experienced to test and evaluate all steps for concentration of REE bearing minerals. Besides the various conventional comminution and concentration technologies, highly innovative processing techniques (e.g. electrodynamic comminution) are available and allow for selective liberation of REE-bearing minerals especially in coarse grained pegmatite material.

High gradient magnetic separation, electrostatics, gravimetric and/or flotation tests can be carried out to further concentrate REE bearing minerals. If applicable a temperature treatment is performed in static and rotary furnaces at GPE’s technical center to drive off volatile species or change crystal structure to improve leaching results.

Extraction of REE’s from a mineral concentrate

A tailor-made processing route for efficient extraction of REE’s from the mineral concentrate will be developed at GPE’s technical center.

In hydrometallurgical tests leaching and purification to high-quality mixed REE compounds is performed. An optimized route for the specific leaching process along with hydrometallurgical purification by precipitation and separation of interfering chemical elements is developed specifically for the obtained mineral concentrate. Special attention is paid to the by-products which may be created during leaching and purification.

A final precipitate of mixed but separated into LREE and HREE compounds will be provided for customer approval.

In the closing decades of the last century China emerged as the major producer of rare earth elements (REE) raw materials, accounting for more than 95% of the world’s production. Most of this production is from the Bayan Obo polymetallic deposit in Inner Mongolia.

In the closing decades of the last century China emerged as the major producer of rare earth elements (REE) raw materials, accounting for more than 95% of the world’s production. Most of this production is from the Bayan Obo polymetallic deposit in Inner Mongolia.

Set against a history of volatile export quotas, future supplies from China will be fundamentally driven by China’s growing domestic demand. Moreover, the Chinese government already started to create a strategic stockpile for rare earth materials including those used to produce electronic and sustainable energy products.

In 2010 Beijing significantly crimped exports of rare-earth minerals citing environmental reasons to clean up a chaotic industry. Seeing prices of the elements soar, investors funded dozens of mine exploration projects around the world. Since then China’s share of global rare-earth output has been shrinking as miners elsewhere capitalized on fears the country controls too much global supply. China’s export policies are the subject of a continuing dispute between Beijing, Washington and others before the World Trade Organization. The WTO in October ruled illegal certain restrictions on Chinese rare-earth exports, though Beijing is expected to appeal the largely symbolic decision.

Mountain Pass, a Californian mine (by Molycorp) and one in Australia (Mount Weld by Lynas) have ramped up recently, with others in South Africa, Vietnam, India and Kazakhstan believed in the construction phase. But those new sources have just been able to cut China’s share of global supply to 86% from 93% between 2011 and 2012. Although new mine production may be able to make up the difference for some lighter elements then facing excess supply for elements such as cerium, lanthanum, and praseodymium, several forecasts show that there will likely be shortfalls of yttrium and several heavier rare earth elements (HREEs), such as, dysprosium, terbium, neodymium, and europium.

Many of the rare earth elements share such similar physical properties that separating individual elements to market specifications is difficult. Only few places outside China have the industrial capacity to separate the different rare earth metals, specifically companies in the U.S., Russia, France, Japan and elsewhere handle some of these steps.

In addition China still dominates processing the mined mineral concentrates into useful ingredients, including metals and magnets. For example, China supplies about 80% of the specialized magnets produced with heavy rare-earth metals that are used in wind power generators and mobile communication products.

This is why GPE already separates the light from the heavy rare earth fraction for customer approval, while special attention is paid to all the valuable by-products which may be created during leaching and purification.

The trend is for a continued increase in the use of REE in many fast developing technologies and applications, especially automotive catalytic converters, permanent magnets, and rechargeable batteries by a forecast average growth rate for REE of 8-11% per annum. However, selective demand requires consideration.

Read More >>

- 75 Edridge Rd, Croydon, Greater London, CR0 1EJ

- 0745-230-4089

- Mon - Fri: 9:00 - 18:00